Description

[vc_row][vc_column][vc_column_text]

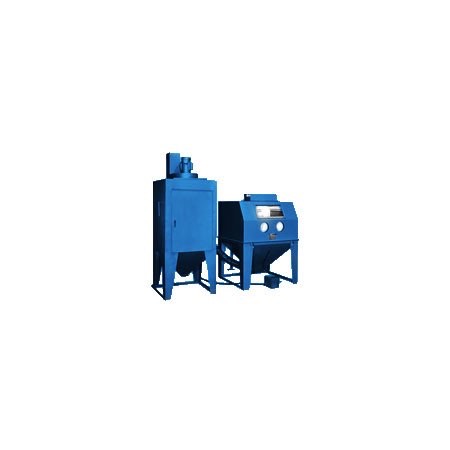

DP Series – Industrial Grade, Direct Pressure, Abrasive Blasting Cabinet System

The DP Series – Industrial Grade, Direct Pressure, Abrasive Blasting Cabinet System is engineered for industrial applications and everyday use. These economical vibratory tumblers are great ‘starter’ systems and for those unfamiliar with mass finishing. Both deburring and polishing can be accomplished on a limited budget.

[/vc_column_text][vc_row_inner][vc_column_inner width=”1/3″][vc_column_text]

Benefits

- Short and Productive Blasting Process

- Industrial Grade Construction

- Side Doors and Flip Tops for Easy Access to Parts

- Adjustable Pressure Valve

- Pressurized, Dense Blast Streams

- Lower Pressure Blasting for Longer Abrasive Media Life

- Media is Recycled to Reduce Operational Costs

- Dust Collector and Abrasive Separator Included (Except for Model DP3630)

- Usable With Nearly All Dry Abrasive Blasting Media

[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/3″][vc_column_text]

Applications

- Paint Stripping

- Surface Preparation

- Scale Removal

- Etching

- Peening

- Cleaning

[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/3″][vc_column_text]

Typical Uses

- Machining Mark Removal

- Surface Preparation for Coating

- Parts Cleaning

- Rust Removal

- Decorative Etching

[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row][vc_column][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Advantages

Abrasive blasting cabinet encloses the blasting environment to provide an efficient blast cleaning while maintaining a clean surrounding work area. Production rates of the pressure blasting machine are dependent on the size of the nozzle, working pressure, compressor capacity, size and type of abrasive media, and distance between the nozzle and the cleaning surface.

Abrasive Blasting cabinet equipped from medium to high-performance applications. The machine frequently utilized to remove the rust from cast products, deburring transmission parts, cleaning strip steel and car crankshafts, pivot shafts, motor squares, and back hub lodgings.

A blast cabinet is a closed-loop system that allows the recycling of the abrasive after blasting. It usually consists of four components; the abrasive blasting system, the containment (cabinet), the dust collection, and the abrasive recycling system. The operator blasts the parts from the outside of the cabinet, viewing the part through a view window, by placing his arms in gloves attached to glove holes on the cabinet, turning the blast on and off using a foot pedal.[/vc_column_text][/vc_column][/vc_row]

The DP Series, Industrial Blasting Cabinets are efficient and productive systems. Designed for small and large shops, these direct pressure systems are ideal for large quantities of blasting or when efficiency and shorter blasting times are required. The DP Series can be used with all types of dry abrasive blast media.

The DP Series, Industrial Blasting Cabinets are efficient and productive systems. Designed for small and large shops, these direct pressure systems are ideal for large quantities of blasting or when efficiency and shorter blasting times are required. The DP Series can be used with all types of dry abrasive blast media.