Description

[vc_row][vc_column][vc_column_text]

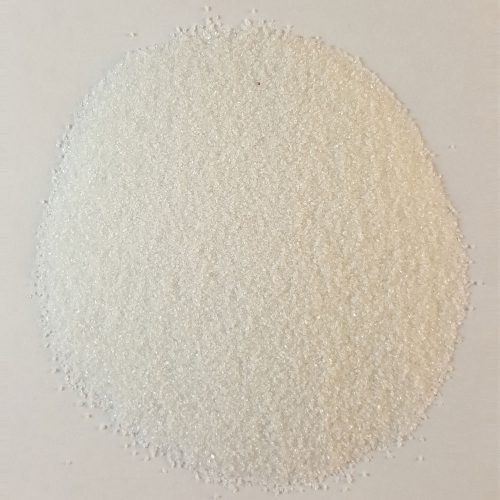

Ceramic Tumbling Media

Ceramic tumbling media is recommended for general purpose polishing, light and heavy deburring, fast and extra fast deburring, and ultra aggressive metal removal. Ceramic media is best for harder metals such as steel and stainless steel but is also used on softer metals such as aluminum. Ceramic media is best suited for very heavy parts.

Durable, inexpensive and highly versatile, ceramic finishing media is the most common media used in mass finishing. It is manufactured in a wide variety of shapes and sizes. Ceramic finishing media is made of silica and other minerals and abrasives that are combined, formed, and fired at a high temperature, producing a very hard, cement-like product. Most ceramic preformed shapes, such as triangles, stars and ellipses, are extruded and cut to the desired length.

The density of ceramic preformed shapes is usually determined by the amount of abrasive incorporated into the mix prior to firing – the more abrasive, the higher the density. This is important because the higher the density, the more “aggressive” the ceramic media will be (faster cutting, rougher surface) and the quicker it will wear. Therefore, dense media is only practical where the objectives cannot be achieved using other methods or where the reduction in cycle time brings a greater value than the extra cost in media consumption.[/vc_column_text][vc_row_inner][vc_column_inner width=”1/3″][vc_column_text]

Benefits

- Highly Durable

- Long Lasting

- Heavier Than Most Tumbling Media

- Fast Cutting Action

- Wide Variety of Shapes and Sizes

- Polishing to Ultra-Aggressive Bonds

- Shorter Cycle Times

- High-Value Media

[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/3″][vc_column_text]

Tumbling Applications

- Deburring Steel and Titanium

- Edge Rounding on Plastics and Other Materials

- Eliminating Machining Lines

- Removing Slag and Dross on Laser Cut Parts

- Forming a Radius

- Heavy and/or Large Parts Tumbling

- Polishing

[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/3″][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row]