TB Series – Industrial Grade, Tumble Blast, Abrasive Blasting System

The Industrial Tumble Blaster TB Series are enclosed, Suction System Cabinet Blast Systems. The slowly rotating basket is ideal for getting a uniform finish on quantities of small parts. Batch processing of parts can be completed automatically with minimal operator involvement. Multiple capacities are available for processing different part sizes and quantities.

TB Series – Industrial Grade, Tumble Blast, Abrasive Blasting System

The TB Series – Industrial Grade, Tumble Blast, Abrasive Blasting System is an enclosed, suction-style blasting systems designed to efficiently blast batches of parts automatically. These cabinets include a basket for holding parts and slowly tumbling them as they are blasted. The random tumbling action ensure that all parts are blasted. Multiple capacities allow for part volumes from 1 quart up to 3 cubic feet

Benefits

- Automatic Blasting of Large Quantities of Small Parts

- Minimal Operator Involvement

- Timer, Dust Collector, and Pressure Regulator Included

- Industrial Grade Construction

- Siphon Blast System

- Media is Recycled to Reduce Operational Costs

- Usable with Nearly All Dry Abrasive Blasting Media

- Ideal For Achieving a Highly Uniform Surface Finish on All Parts

Applications

- Deflashing

- Light Deburring

- Paint Stripping

- Surface Preparation

- Scale Removal

- Peening

Typical Uses

- Machining Mark Removal

- Surface Preparation For Coating

- Parts Cleaning

- Rust Removal

- Blasting of Quantities of Small Parts

Specifications

TB Series Specifications

TB Series Model Comparison Chart |

||||

|---|---|---|---|---|

Model |

Capacity(Volume) |

Capacity(Weight) |

# of Guns |

Notes |

| TB-1 | 1 Quart | 8 lbs. | 1 | Bench Model |

| TB-1412 | 0.5 ft3 | 50 lbs. | 1 | Production Floor Model |

| TB-2424 | 1.0 ft3 | 150 lbs. | 2 | Production Floor Model |

| TB-2 | 2.0 ft3 | 80 lbs. | 2 | Extra Large Capacity |

| TB-3 | 3.0 ft3 | 150 lbs. | 2 | Extra Large Capacity |

TB Series Model Components & Features

TB-1 Model Specifications |

|

|---|---|

Barrel |

|

Capacity |

|

Drive |

|

Cabinet |

|

Dust Collector |

|

Controls |

|

Air Gun and Nozzle |

|

Air Pressure |

|

Inside Work Area |

|

Measurements |

|

TB-1412 & TB-2424 Model Specifications |

||

|---|---|---|

Model |

TB-1412 | TB-2424 |

Barrel |

|

|

Capacity |

|

|

Drive |

|

|

Cabinet |

|

|

Dust Collector |

||

Controls |

|

|

Air Pressure |

|

|

Floor Space |

|

|

TB-2 & TB-3 Model Specifications |

|

|---|---|

Barrel |

|

Capacity |

|

Drive |

|

Cabinet |

|

Dust Collector |

|

Controls |

|

Air Pressure |

|

Noise Level |

|

Floor Space |

|

Additional Information

| Selected Package Gross Weight | 1000 lbs |

|---|

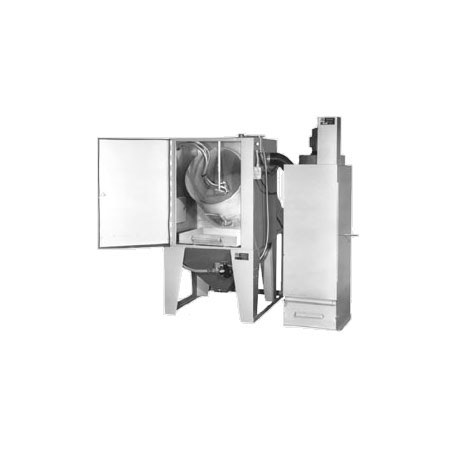

TB1 - Closed

TB1 - Closed

TB1 - Open

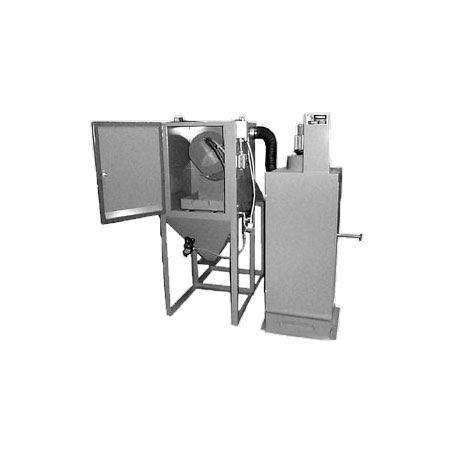

TB1412 - Open

TB 2424 - Open

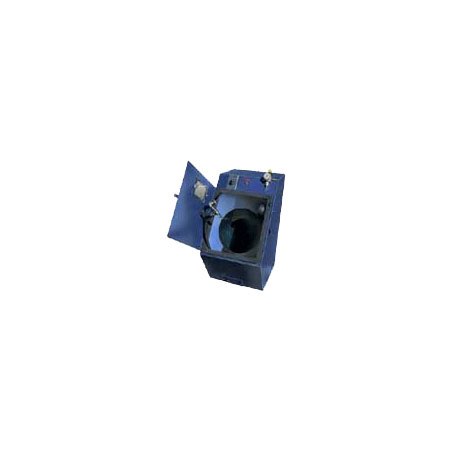

TB2 - Open

TB2 - Closed

TB3 - Open

TB3 - Closed

Related Products

-

White Aluminum Oxide Grit

$39.95 – $265.00White Aluminum Oxide Grit is a >99% ultra-pure grade of abrasive media. It is increasingly being used in critical, high-performance processes that are sensitive to contamination and cleanliness.

-

HDP Series – Heavy-Duty Grade, Direct Pressure, Abrasive Blasting Cabinet System

$17,995.00The HDP Series, Heavy Duty Blasting Cabinets are designed for large shops and when high volume blasting is required. These highly customizable systems can be upgraded and modified to meet specific applications and requirements. A standard exterior track allows easy part loading and unloading. The HDP Series is our most productive blast system.

-

DP Series – Industrial Grade, Direct Pressure, Abrasive Blasting Cabinet System

$4,595.00 The DP Series, Industrial Blasting Cabinets are efficient and productive systems. Designed for small and large shops, these direct pressure systems are ideal for large quantities of blasting or when efficiency and shorter blasting times are required. The DP Series can be used with all types of dry abrasive blast media.

The DP Series, Industrial Blasting Cabinets are efficient and productive systems. Designed for small and large shops, these direct pressure systems are ideal for large quantities of blasting or when efficiency and shorter blasting times are required. The DP Series can be used with all types of dry abrasive blast media. -

SS Series – Industrial Grade, Suction Style, Abrasive Blasting Cabinet System

$995.00The SS Series, Industrial Suction Sandblaster Cabinet is the most economical and commonly used blast cabinet. Designed for small shops and light production areas, the siphon/suction systems are ideal for quick blasting and surface prep. The SS Series can be used with all types of dry abrasive blast media.