Tumbling Media

TUMBLING MEDIA FOR BARREL & VIBRATORY FINISHING EQUIPMENT

In the tumbling process, a preformed media is the rigid agent that abrades the given part and removes the unwanted material. The advantage of this media is the inclusion of a bonding agent that continuously recedes and exposes more abrasive particles. In result, they maintain a relatively consistent removal rate over at least have the size of its shape.

Your desired surface finish determines the needed characteristics of your chosen media, such as size, shape, internal particle size, and mineral composition. Often times, a project requires a trial process before the development of a mass finishing project. We offer free test runs of your parts in our laboratory to assist in this manner. When finished, we return the parts for your evaluation.

Types

- Preformed Shapes and Sizes – Ceramic, Plastic, Synthetic, and Others

- Hardwood Media for Dry Tumbling

- Steel Media for Burnishing and Work Hardening

- Abrasives for Aggressive Deburring to High Polishing

- Treated Media for Light Cutting to Near Mirror Finishes

Applications

- Deburring

- Cleaning

- Deflashing

- Edge Radiusing

- Polishing

- Burnishing

- Removing Machine Marks

- Sanding

- Scale and/or Rust Removal

Typical Uses

- Machine Mark Removal

- Rust Removal and Cleaning

- Polishing Metal and Plastic Parts

- Finishing 3D Printed Parts

- Sanding Wood Parts

- Deburring Metals and Plastics

- Deflashing Extruded Parts

Tumbling media is a preformed abrasive material that is used for finishing and polishing parts made of various materials. It is mainly used with finishing equipment so that tumbling media and parts to scrub against each other, producing thorough and precise abrasiveness to remove burrs.

Showing all 14 results

-

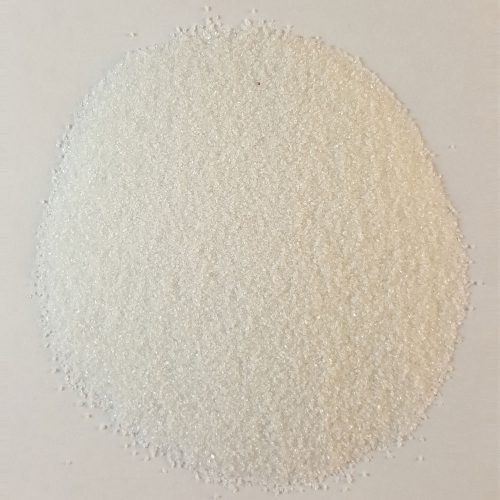

White Aluminum Oxide Grit

$39.95 – $265.00 Select options -

Aluminum Oxide Grit (Standard)

$39.95 – $266.50 Select options -

Silicon Carbide Grit

$39.95 – $430.00 Select options -

Hardwood Tumbling Media

$49.95 – $645.00 Select options -

Premium Ceramic Tumbling Media

$34.95 – $728.75 Select options -

Walnut Shell Grit

$39.95 – $105.00 Select options -

Corn Cob Grit

$39.95 – $90.00 Select options -

Premium Treated Media

$39.95 – $18,585.00 Select options -

Stainless Steel Tumbling Media

$49.95 – $2,779.00 Select options -

White Aluminum Oxide Grit (Test)

$106.75 Read more -

Plastic Tumbling Media

$3.27 Request a Quote -

High Density Ceramic Tumbling Media

$3.66 Request a Quote -

Ceramic Tumbling Media

$2.08 Request a Quote -

Carbon Steel Tumbling Media

Read more