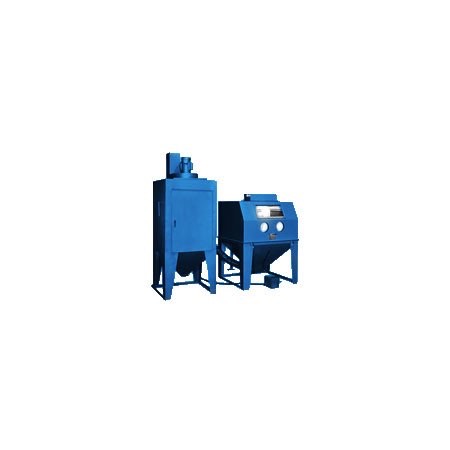

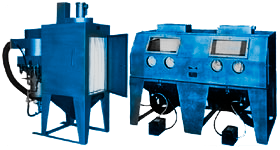

DP Series – Industrial Grade, Direct Pressure, Abrasive Blasting Cabinet System

The DP Series, Industrial Blasting Cabinets are efficient and productive systems. Designed for small and large shops, these direct pressure systems are ideal for large quantities of blasting or when efficiency and shorter blasting times are required. The DP Series can be used with all types of dry abrasive blast media.

The DP Series, Industrial Blasting Cabinets are efficient and productive systems. Designed for small and large shops, these direct pressure systems are ideal for large quantities of blasting or when efficiency and shorter blasting times are required. The DP Series can be used with all types of dry abrasive blast media.

DP Series – Industrial Grade, Direct Pressure, Abrasive Blasting Cabinet System

The DP Series – Industrial Grade, Direct Pressure, Abrasive Blasting Cabinet System is engineered for industrial applications and everyday use. These economical vibratory tumblers are great ‘starter’ systems and for those unfamiliar with mass finishing. Both deburring and polishing can be accomplished on a limited budget.

Benefits

- Short and Productive Blasting Process

- Industrial Grade Construction

- Side Doors and Flip Tops for Easy Access to Parts

- Adjustable Pressure Valve

- Pressurized, Dense Blast Streams

- Lower Pressure Blasting for Longer Abrasive Media Life

- Media is Recycled to Reduce Operational Costs

- Dust Collector and Abrasive Separator Included (Except for Model DP3630)

- Usable With Nearly All Dry Abrasive Blasting Media

Applications

- Paint Stripping

- Surface Preparation

- Scale Removal

- Etching

- Peening

- Cleaning

Typical Uses

- Machining Mark Removal

- Surface Preparation for Coating

- Parts Cleaning

- Rust Removal

- Decorative Etching

Advantages

Abrasive blasting cabinet encloses the blasting environment to provide an efficient blast cleaning while maintaining a clean surrounding work area. Production rates of the pressure blasting machine are dependent on the size of the nozzle, working pressure, compressor capacity, size and type of abrasive media, and distance between the nozzle and the cleaning surface.

Abrasive Blasting cabinet equipped from medium to high-performance applications. The machine frequently utilized to remove the rust from cast products, deburring transmission parts, cleaning strip steel and car crankshafts, pivot shafts, motor squares, and back hub lodgings.

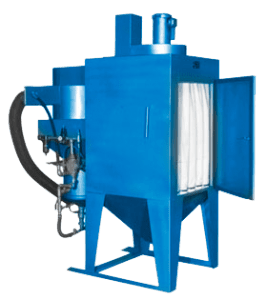

A blast cabinet is a closed-loop system that allows the recycling of the abrasive after blasting. It usually consists of four components; the abrasive blasting system, the containment (cabinet), the dust collection, and the abrasive recycling system. The operator blasts the parts from the outside of the cabinet, viewing the part through a view window, by placing his arms in gloves attached to glove holes on the cabinet, turning the blast on and off using a foot pedal.

Specifications

DP Series Specifications

DP Series Components & Features |

|

|---|---|

Cabinet |

|

Window |

|

Lighting |

|

Gloves |

|

Gun System |

|

Pressure

|

With a Full Pot Using a 1/4" Nozzle and Blasting at 50 PSI the Pressure Pot Will Empty in About 10 Minutes. When the Foot Pedal is Released it Takes About 10 Seconds for the Pressure in the System to Bleed Out Through the Nozzle. The Plunger in the Pressure Pot Will Then Drop Allowing the Cleaned Media in the Storage Hopper to Refill it. Refilling Can Take 20-60 Seconds Depending on Media Type and Grit Size. |

Dust Collectors |

|

Air Pressure Gauge |

|

Air Line Water Filter |

|

Electrical |

|

Abrasive Separator |

|

Air Cylinder |

|

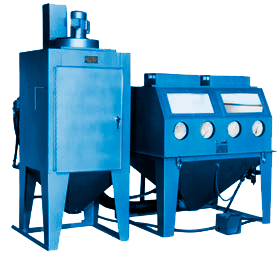

DP Series Model Components & Features |

||||

|---|---|---|---|---|

Model |

Style |

Dimensions(Width x Height x Depth) |

Doors |

Windows |

|

DP3630

|

Cabinet | Inside: 36" x 23" x 30" Overall: 41" x 68" x 35" Floor Space: 41" x 67" |

Two 14" x 20" Side Doors

One 36" x 13" Lid Opening |

One 12" x 24" |

|

DP3636

|

Cabinet | Inside: 36" x 36" x 36" Overall: 40" x 78" x 37" Floor Space: 96" x 85" |

Two 28" x 30" Side Doors | One 12" x 24" |

|

DP4040S

|

Split-Level Cabinet | Inside: 40" x 31" x 40" Overall: 44" x 71" x 66" Closed 44" x 77" x 66" Open Floor Space: 96" x 71" |

One 20" x 30" Side Door

One 40" x 40" Flip Top Lid |

One 12" x 24" |

| DP4836 | Cabinet | Inside: 48" x 36" x 36" Overall: 53" x 78" x 37" Floor Space: 104" x 90" |

Two 28" x 30" Side Doors | One 12" x 24" |

|

DP4848S

|

Split-Level Cabinet | Inside: 48" x 31" x 48" Overall: 52" x 71" x 74" Closed 52" x 71" x 77" Open Floor Space: 100" x 77" |

One 20" x 36" Side Door

One 48" x 48" Flip Top Lid |

One 12" x 24" |

| DP6030S | Split-Level Cabinet

Dual Workstations For a Single Operator |

Inside: 60" x 31" x 30" Overall: 64" x 71" x 56" Closed 64" x 71" x 60" Open Floor Space: 111" x 77" |

One 17" x 16" Side Door

One 60" x 30" Flip Top Lid |

Two 12" x 24" |

|

DP6048S

|

Split-Level Cabinet

Dual Workstations For a Single Operator |

Inside: 60" x 31" x 48" Overall: 65" x 71" x 74" Closed 65" x 71" x 77" Open Floor Space: 111" x 77" |

One 20" x 36" Side Door

One 60" x 48" Flip Top Lid |

Two 12" x 24" |

| DP7248S | Split-Level Cabinet

Dual Workstations For a Single Operator |

Inside: 72" x 31" x 48" Overall: 75" x 71" x 74" Closed 75" x 71" x 77" Open Floor Space: 127" x 90" |

One 20" x 36" Side Door

One 72" x 48" Flip Top Lid |

Two 12" x 24" |

|

DP9648S

|

Split-Level Cabinet

Dual Workstations For a Two Operators or Dual Workstations For a Single Operator |

Inside: 96" x 31" x 48" Overall: 102" x 71" x 74" Closed 102" x 71" x 77" Open Floor Space: 200" x 90" |

Two 36" x 20" Side Doors

One 96" x 48" Flip Top Lid |

Two 12" x 24" |

|

The DP850 Retrofit Package Converts our Siphon Type Cabinet (SS Series) to a Direct Pressure Unit. This Unit Can be Adapted to Any Standard Siphon-Type Cabinet With a Minimum of Effort to Afford You the Speed and Efficiency of Direct Pressure Blasting. Includes 850 CFM Abrasive Separator. Abrasive Capacity: 150 lb. Overall Dimensions: 70" x 104" x 40". Additional Piping and Modifications Must Be Made to Existing Cabinet. |

Additional Information

| Selected Package Gross Weight | 1000 lbs |

|---|

DP3630

DP 3636

4040S

4848S

6048

9648

Related Products

-

SS Series – Industrial Grade, Suction Style, Abrasive Blasting Cabinet System

$995.00The SS Series, Industrial Suction Sandblaster Cabinet is the most economical and commonly used blast cabinet. Designed for small shops and light production areas, the siphon/suction systems are ideal for quick blasting and surface prep. The SS Series can be used with all types of dry abrasive blast media.

-

TB Series – Industrial Grade, Tumble Blast, Abrasive Blasting System

$4,395.00The Industrial Tumble Blaster TB Series are enclosed, Suction System Cabinet Blast Systems. The slowly rotating basket is ideal for getting a uniform finish on quantities of small parts. Batch processing of parts can be completed automatically with minimal operator involvement. Multiple capacities are available for processing different part sizes and quantities.

-

HDP Series – Heavy-Duty Grade, Direct Pressure, Abrasive Blasting Cabinet System

$17,995.00The HDP Series, Heavy Duty Blasting Cabinets are designed for large shops and when high volume blasting is required. These highly customizable systems can be upgraded and modified to meet specific applications and requirements. A standard exterior track allows easy part loading and unloading. The HDP Series is our most productive blast system.

-

Glass Beads

$39.95 – $94.50 Glass Beads are a round, spherical media that produce a softer and brighter finish angular medias. Glass Beads are used for blasting, peening, honing, cleaning, and light deburring.

Glass Beads are a round, spherical media that produce a softer and brighter finish angular medias. Glass Beads are used for blasting, peening, honing, cleaning, and light deburring.