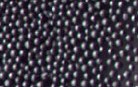

Steel Shot

Steel Shot is ideal for peening applications to impart a clean, smooth finish. This dense, smooth media can be used up to 3,000 times and produces minimal dust during the blasting process.

Steel Shot is ideal for peening applications to impart a clean, smooth finish. This dense, smooth media can be used up to 3,000 times and produces minimal dust during the blasting process.

Steel Shot

Steel shot blasting is the most widely used process for cleaning, stripping and improving a metal surface. The grade or size of steel shot will determine the ultimate finish achieved on the surface of the metal. The round ball shape of the steel shot produces a clean, smooth and polished surface through a peening action created by the acceleration of the shot. In a peening application, steel shot is also used to impart compressive strength to torque or load bearing metal parts such as crankshafts, engine turbine blades and heavy-duty springs.

Smaller steel shot will result in a smoother and more polished surface. Larger shot will clean more aggressively but produce a rougher surface. Both air powered and wheel blast systems can be used to accelerate the steel shot onto the surface of the part. Due to the hardness and density of steel shot, it can be recycled as much as 3000 times before replacement. Since steel shot does not use an abrasive process and a minimal amount of dust is created in the blasting process.

Benefits

- Extreme Durability

- Very High Recyclability

- Spherical in Shape

- Magnetic

- Used in Both Wheel Blasting and Pneumatic (Air) Blasting

- Multiple Hardnesses Available

- Very Low Dusting

Applications

- Shot Peening

- Surface Preparation

- Polishing

- Cleaning

Steel Shot Blasting

Steel Shot blasting is a technique used to perfect or clean steel when specific surface finishes are required. Steel shot is utilized in pretty much every industry imaginable. These incorporate massive construction, shipbuilding, rail, and auxiliary manufacturing.

Blast cleaning with steel shot is a vital operation at various stages of primary metal production. The different varieties and the size of the steel shot give an excellent result on the metal surface. It is one of the most cost effective since it can be recycled hundreds if not thousands of times due to its robustness and durability.

A larger steel shot blasting cleans a rougher surface thoroughly. In order to accelerate steel shot on the surface, both wheel blast and air pneumatic systems are used.

Advantages of Steel Shot Blasting

- It provides an excellent result on the metal surface finish.

- Extremely high durability

- Cost-effective & recycle ability

- Both wheel blast systems and air power can be used

- Remove surface contamination and provide a spotless surface

Steel shot blasting produces the least dust because its process is less abrasive and the media does not break down. Steel shot is used to overcome condensate strength to torque or loading metal parts such as engine turbine blades, crankshafts, and heavy-duty spring.

Steel Shot Blasting is a surface finishing method that prevents metal fatigue or cracking as well as for cleaning and surface hardening. In this method, the role of a shot is to remove rust, impurities, surface contamination, or other remains that can affect metal strength. It is environmental-friendly and a rapid, cost-effective surface finishing method that is used for cleaning, polishing metal, and other surfaces by applying a high-speed stream of round shot media.

Steel Shot Blasting also has multiple uses wherein it can remove hard scrapes, scales, and burrs, and is an excellent rust remover. Since it does effectively clean surface corrosion that may interfere with the part’s integrity, blasting becomes a reliable approach to surface treatment.

Specifications

Steel Shot Sizes And Finishes

Steel Shot Specifications |

|||

|---|---|---|---|

Shot Grade |

Approximate Size |

Finish |

Applications |

| S-070 | 0.007" | Fine, smooth shot finish. Excellent coverage. | Blasting of relatively small ferrous and non-ferrous castings. Removal of light scale from foreign and heat treated parts. Blasting of machined parts. Removal of mill scale, rust and other deposits. |

| S-110 | 0.011" | ||

| S-170 | 0.017" | ||

| S-230 | 0.023" | Medium, light shot finish. Good coverage. | Blasting of grey iron, malleable iron, light steel castings, medium forgings, heat-treated parts and heavy mill scale - rust and other deposits. |

| S-280 | 0.028" | ||

| S-330 | 0.033" | ||

| S-390 | 0.039" | Average to heavy shot finish. Average coverage. | Blasting of steel, heavy malleable iron and grey iron castings. Removal of scale from large billets, slabs - rust and other deposits. |

| S-460 | 0.046" | ||

| S-550 | 0.055" | ||

| S-660 | 0.066" | Rough coverage. Adequate for most applications. | Heavy steel castings. Removal of tough, heavy scale. |

| S-780 | 0.078" | ||

Additional Information

| Selected Package Gross Weight | 50 lbs |

|---|---|

| Shot Grade | S-780, S-660, S-550, S-460, S-390, S-330, S-280, S-230, S-170, S-110, S-070 |

| Package Size | 1 lb, 5 lb, 10 lb, 25 lb, 50 lb, 55 lb, 2,000 lb, 2,200 lb |

Related Products

-

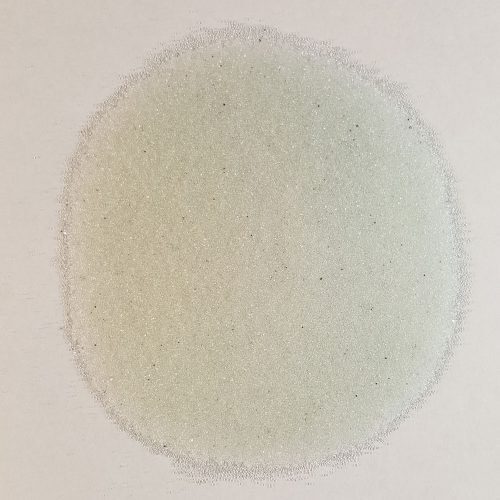

Glass Beads

$39.95 – $94.50 Glass Beads are a round, spherical media that produce a softer and brighter finish angular medias. Glass Beads are used for blasting, peening, honing, cleaning, and light deburring.

Glass Beads are a round, spherical media that produce a softer and brighter finish angular medias. Glass Beads are used for blasting, peening, honing, cleaning, and light deburring. -

DP Series – Industrial Grade, Direct Pressure, Abrasive Blasting Cabinet System

$4,595.00 The DP Series, Industrial Blasting Cabinets are efficient and productive systems. Designed for small and large shops, these direct pressure systems are ideal for large quantities of blasting or when efficiency and shorter blasting times are required. The DP Series can be used with all types of dry abrasive blast media.

The DP Series, Industrial Blasting Cabinets are efficient and productive systems. Designed for small and large shops, these direct pressure systems are ideal for large quantities of blasting or when efficiency and shorter blasting times are required. The DP Series can be used with all types of dry abrasive blast media. -

Aluminum Oxide Grit (Standard)

$39.95 – $266.50Aluminum Oxide Grit (Standard) is a sharp, long lasting abrasive media that is highly efficient and highly reusable. Harder than most blast media, Aluminum Oxide Blast Media, will clean and etch quickly on all type of surfaces.

-

Steel Grit

$54.95 – $159.50 Steel Grit is an angular, carbon steel media designed for quick and effective removal of surface contaminants and coatings. Steel Grit is softer than other media and is less likely to fracture leaving an etched finish.

Steel Grit is an angular, carbon steel media designed for quick and effective removal of surface contaminants and coatings. Steel Grit is softer than other media and is less likely to fracture leaving an etched finish.